When considering an epoxy floor coating for your home or business in the Akron and Cleveland area, understanding the industry’s most frequently used terms can help you make informed decisions about your flooring options. In this guide, we provide some epoxy flooring definitions, adding details specific to the Northeast Ohio region.

Epoxy Flooring Definitions: Coating Types

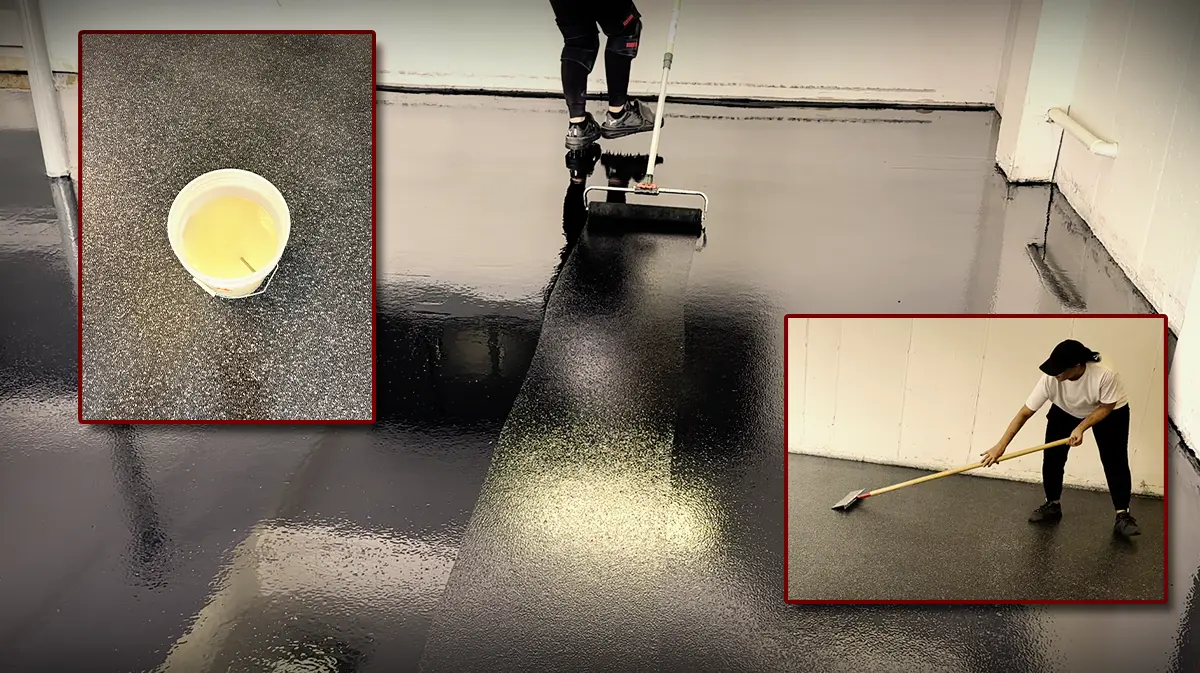

- Epoxy Coating: Epoxy is a durable, long-lasting coating created by mixing a resin (Part A) and hardener (Part B) components. When applied to concrete surfaces, this slow-curing coating forms a strong bond. It resists chemical spills, moisture, and heavy foot traffic. In Akron and Cleveland, where concrete moisture content can be high, moisture-mitigating epoxies are excellent primer coatings (direct-to-concrete). However, epoxies can amber and fade when exposed to UV light. Consequently, these coatings are best used as color coats for interior spaces and/or as primer coats.

- Polyaspartic Coating: Polyaspartics are fast-cure coatings (they can even cure in low temperatures, useful in Ohio’s colder months). They provide extreme UV stability and chemical resistance, so floors exposed to sunlight won’t yellow over time. The Achilles heel? Polyaspartic coatings are poor primer coats when applied direct-to-concrete.

- Polyurethane: This flexible topcoat is typically applied over epoxy to add additional protection. Polyurethanes resist UV damage and abrasion, ensuring the underlying coatings lasts longer. Especially useful in exterior areas exposed to sunlight. Albeit, they can be odorous (interior installs can be a problem). More importantly, they cannot be used in garages as they are susceptible to hot-tire transfer.

Epoxy Flooring Definitions: Decorative Coating Systems

- Flake Epoxy Floor System: A flake epoxy floor system involves broadcasting colored vinyl acetate (thermoplastic) or mica flakes into the base layer of epoxy. The flakes add depth and texture and assist as an anti-skid, valuable in Ohio’s wet, snowy winters. This system also enhances the aesthetic appeal, as it allows for customization in color and design.

- Mica Flakes: Mica flakes are natural minerals added to the coating to enhance the floor’s reflectivity. This option is often used in commercial properties or high-end residential garages. The shimmer of mica creates a dynamic look that changes with the lighting, making it a popular choice for showrooms.

- Full Flake Epoxy Floor System: The full chip system covers the entire surface with flakes, resulting in a thicker, more durable floor. This system is especially useful in high-traffic areas like commercial garages, auto shops, or busy basements. In Akron and Cleveland, where floor coatings need to withstand moisture and heavy use, this system provides both aesthetic value and practicality.

Epoxy Flooring Definitions: Miscellaneous

- Waterproofing Basement: Epoxy and polyaspartic coatings can also be used to waterproof basements. This is crucial in Northeast Ohio, where rain and snowmelt can lead to damp conditions. These coatings create a moisture barrier that prevents water from seeping through the concrete, protecting your basement from mold and mildew growth.

- Garage Floor Coating: A comprehensive term that includes layered epoxy and polyurea-polyaspartic coatings. Garage floor coatings in Akron and Cleveland protect against oil spills, road salts, and the effects of freeze-thaw cycles. Furthermore, these coatings provide a durable, slip-resistant surface that enhances both the appearance and functionality of your garage.

- Concrete Floor Paint: This is just a casual term used for epoxy flooring, not so much a scientific definition. Real paints should never be used to coat a garage floor; they just don’t last.

- Moisture Control: In Ohio’s variable climate, moisture management is critical. The concrete in garages and basements can absorb water, leading to potential issues like cracking, peeling, or delamination of coatings. Moisture mitigation techniques, such as vapor barriers and moisture-resistant epoxy primers, help prevent these problems and ensure the longevity of your epoxy floor.

Conclusion

Choosing the right coating for your Akron or Cleveland home or business means understanding the various options available. Whether you’re looking for moisture resistance, aesthetic appeal, or sheer durability, knowing these terms will help you make an informed decision. From epoxy and polyaspartic to decorative systems like mica flakes and full chip coatings, each option offers unique benefits suited to Ohio’s climate.