In the heart of Ohio, where Akron and Cleveland face a mix of humid summers and cold winters, garage floors need special care to remain durable and attractive. Proper concrete preparation is key to achieving a long-lasting epoxy coating, ensuring your garage floor withstands both the elements and the wear and tear of daily use.

Concrete Surface Profile

First off, some definitions: Concrete surface profile (CSP) is crucial for the success of epoxy coatings. The International Concrete Repair Institute ranks concrete roughness from CSP 1 (smoothest) to CSP 10 (roughest). For effective bonding, a CSP of at least 3 is necessary. Techniques like low-pressure water jetting and acid etching typically result in CSPs below 2, which aren’t sufficient for durable adhesion and can cause peeling, especially in high-traffic areas. On the other hand, methods such as sandblasting and rotomilling can create overly rough surfaces with CSPs above 4, which are usually too harsh for residential use.

Equipment Required to Prepare for Epoxy Coatings

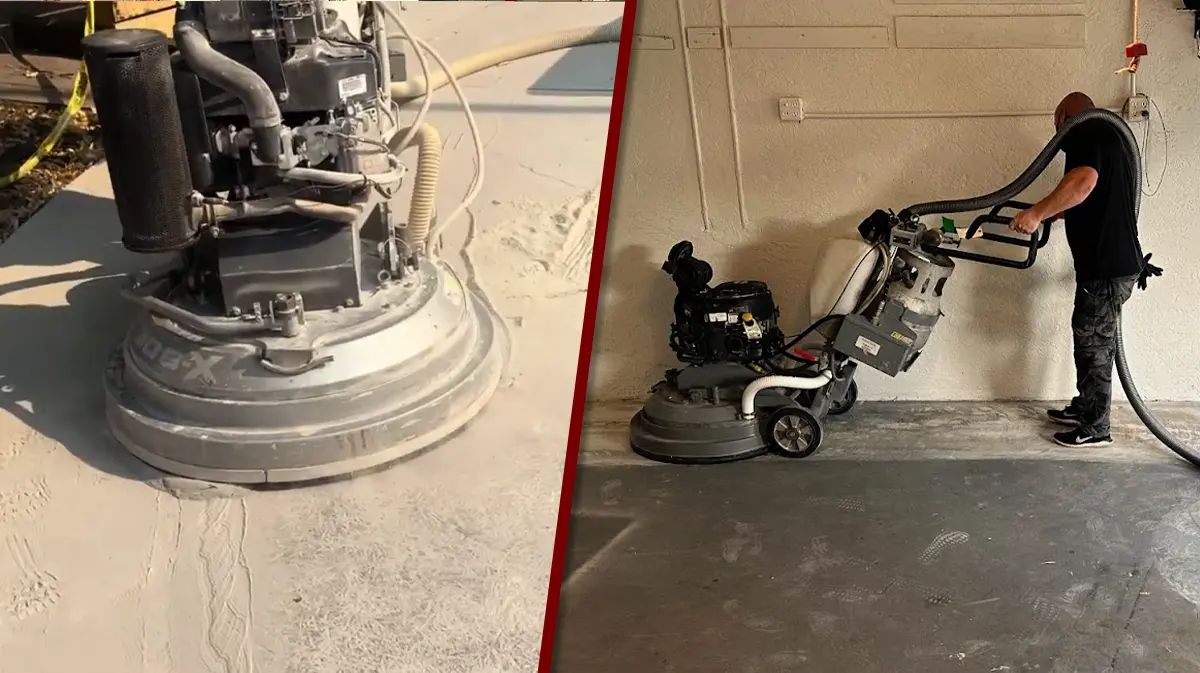

Achieving the right CSP is best done through grinding. Grinders can produce CSPs between 3 and 4, making them ideal for prepping concrete for epoxy coatings. Propane grinders, in particular, stand out due to their superior power and efficiency compared to electric grinders. Despite a higher initial investment, propane grinders reduce labor time and overall costs, so it’s just a better value overall. They are also safer in commercial environments because they don’t require electricity, minimizing the risk of electrical hazards in damp conditions. On top of all that, propane grinders emit near-zero exhaust, making them suitable for indoor use.

DIY Attempts

Many DIY epoxy coating attempts fail due to inadequate concrete preparation (too many to count). The reality is that the specialized equipment needed to achieve the proper CSP is often too expensive for most DIYers. Professional contractors bring the necessary expertise and equipment to ensure the concrete is correctly prepared, resulting in a high-quality, durable epoxy coating.

Beyond weather considerations, local building codes in Akron and Cleveland add another layer of complexity to garage floor preparation and coating. Ensuring compliance with these regulations is essential not only for safety but also for maintaining and enhancing property value. Professional contractors are familiar with these local requirements and can navigate them efficiently, providing you with a compliant and durable garage floor.

Investing in professional concrete preparation services ensures that your garage floor is ready to face both environmental and regulatory challenges. Properly prepped concrete offers a stable foundation for epoxy coatings, leading to a long-lasting and attractive finish.