Imagine this: You’ve just had a brand-new garage floor installed in your Northeast Ohio home. It looks great on day one—smooth finish, bold color, and a quick “1-day” turnaround. But fast forward and things start to change. Peeling. Bubbling. Cracks.

This is what can go wrong when the wrong base coat is used—and it’s more common than you think. At Forte Garage Floor Coating, we prevent these issues by using garage floor epoxy as the foundation of every coating system.

What Happens When Polyurea-Polyaspartic Is Used as the Base Coat?

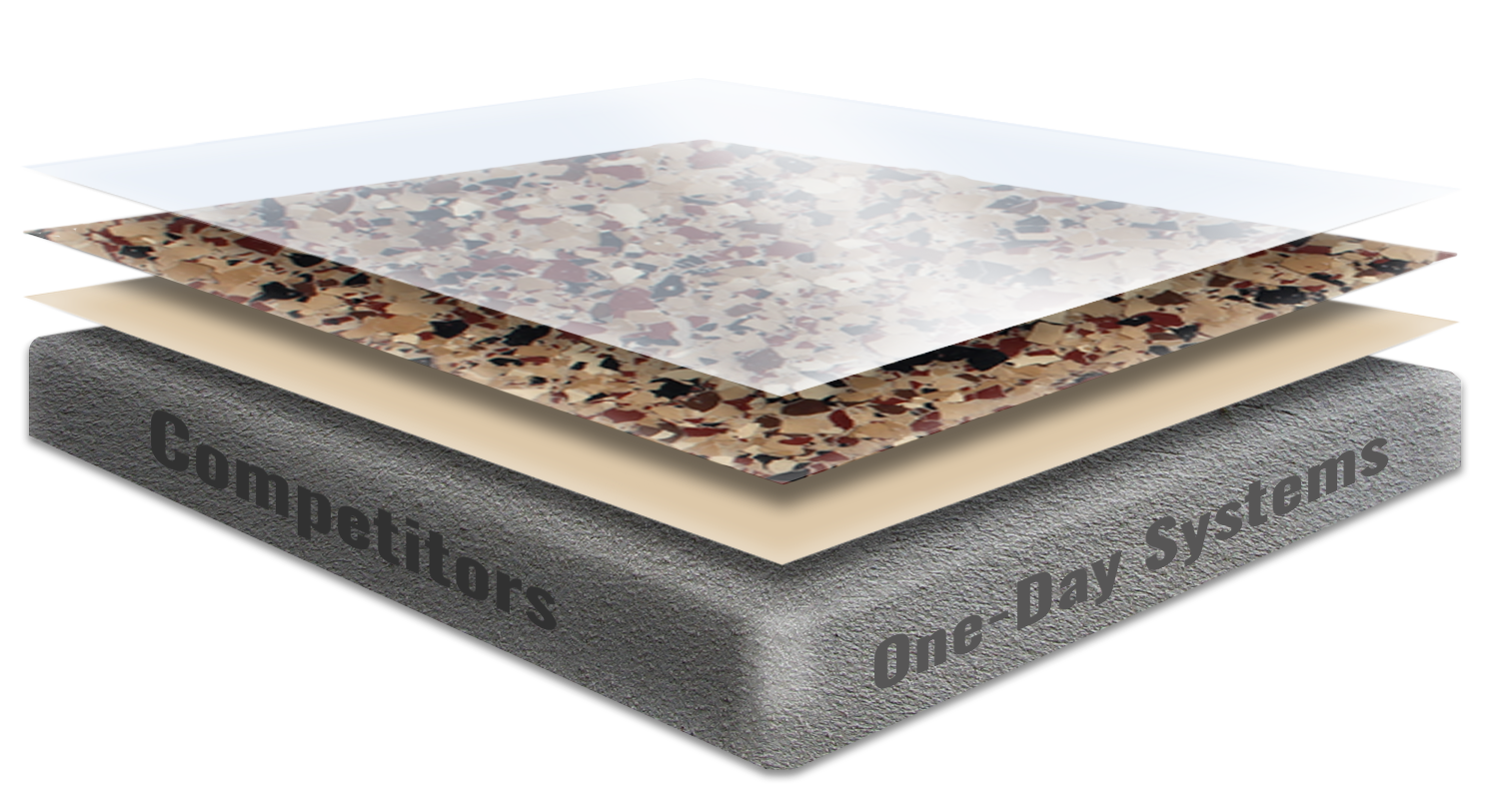

Many 1-day systems use polyurea and polyaspartics as both the base coat (direct-to-concrete) and topcoat. These coatings cure exceptionally fast…and faster still in the presence of high humidity or moisture in the concrete slab. Using fast-cure coatings as both the base coat and single top coat is great for quick installs—but not for long-term durability.

- The problem: Polyureas and polyaspartics cure so quickly, they simply don’t have time to deeply penetrate the concrete slab. And, due to their chemical nature, they can’t be applied thickly.

- The result: A thin, poorly-adhering base coat. Given that the entire coating system is only as strong as it’s base coat, this means the layered coating can lift, flake, or delaminate. This is not uncommon in Akron and Cleveland as moisture wicks up the concrete slab producing upward hydrostatic pressures.

In contrast, garage floor epoxy cures slowly, giving it time to penetrate and bond tightly to the slab.

Moisture Can Ruin a Garage Floor—If the Base Coat Fails

Even when the surface looks dry, moisture vapor can rise from below the slab. In Northeast Ohio, where seasonal moisture is unavoidable, this can cause major coating failures. A high-build, moisture-mitigating, 100%-solids epoxy provides a dependable base layer, helping to prevent future bubbling and separation caused by hydrostatic pressure. Polyurea-polyaspartics just can’t offer that same level of defense; they’re excellent top coats, but lousy base coats, especially in the presence of moisture.

Thin Coats Wear Down Fast

In addition, due to their chemical properties, polyureas and polyaspartics can only be applied thinly, which means less strength and durability when used as base coats. Over time, moisture vapor, high traffic, and general wear and tear weakens the thin, poorly-penetrating base. Conversely, garage floor epoxy is slower-curing and goes down thicker, forming a deeply penetrating, strong base that can take a beating.

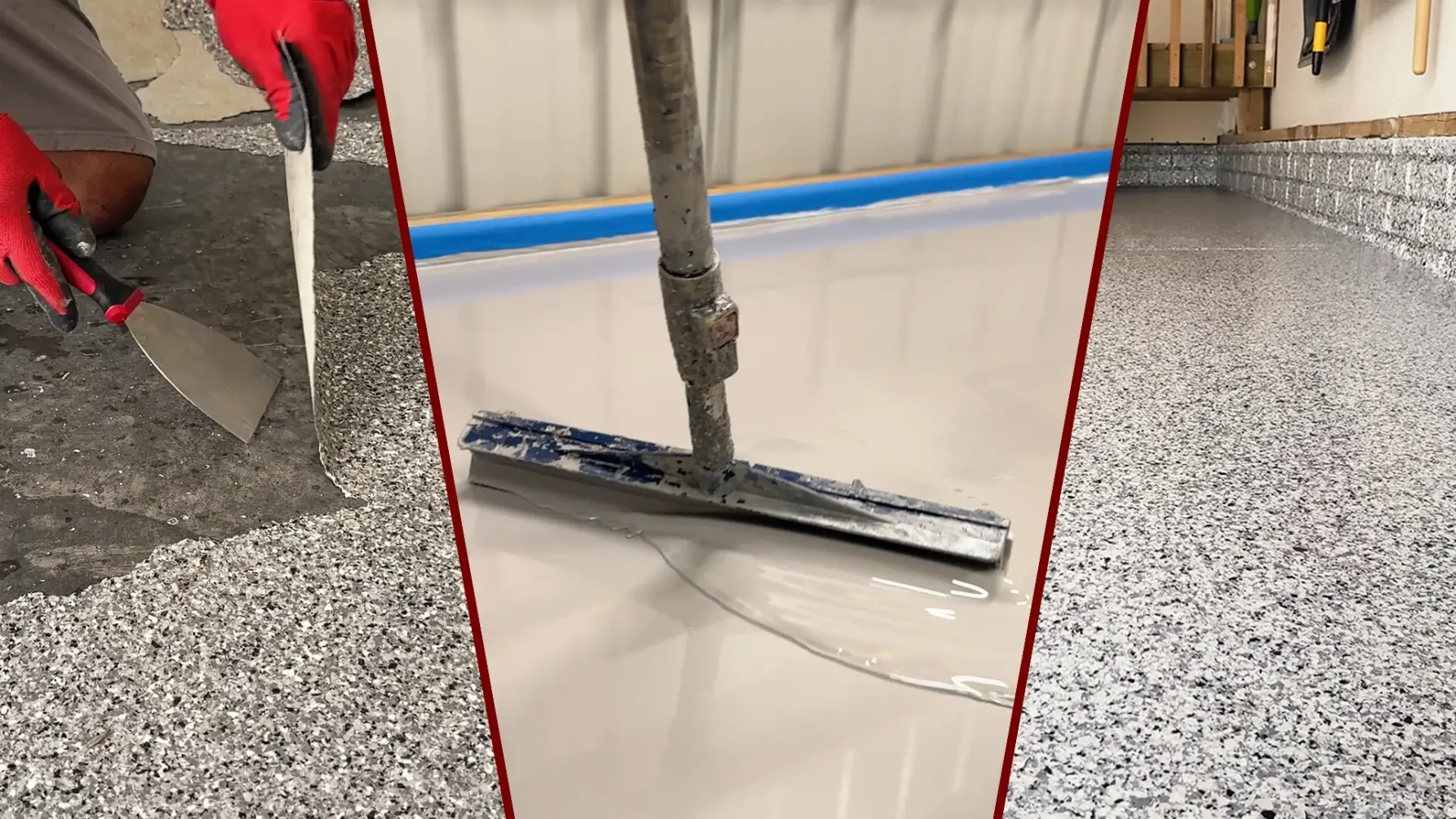

At Forte Garage Floor Coating, We Build It to Last

Our 2-day system includes:

- A high-build (thick), moisture-mitigating, 100%-solids garage floor epoxy base coat

- Two (not just one) 100%-solids polyaspartic topcoats for UV protection and longevity

Skip the shortcuts. Get the garage floor that holds up season after season in Northeast Ohio with Forte Garage Floor Coating.