When it comes to garage floor coatings, there are two main installation options: a 1-day polyurea-polyaspartic system or a 2-day garage floor coating that uses both epoxy and polyaspartic products. At first glance, the 1-day system might seem ideal, especially for busy homeowners in the Akron and Cleveland area. After all, it offers a fast turnaround time, allowing you to use your garage within 24 hours. We know that modern life always seems to prioritize speed, but is faster really always better?

The Downside of a 1-Day System

Yes, the idea of a quick fix sounds good, the reality is that 1-day coating systems often cut corners, leading to problems down the road. Here’s what you should consider before opting for a 1-day garage floor coating:

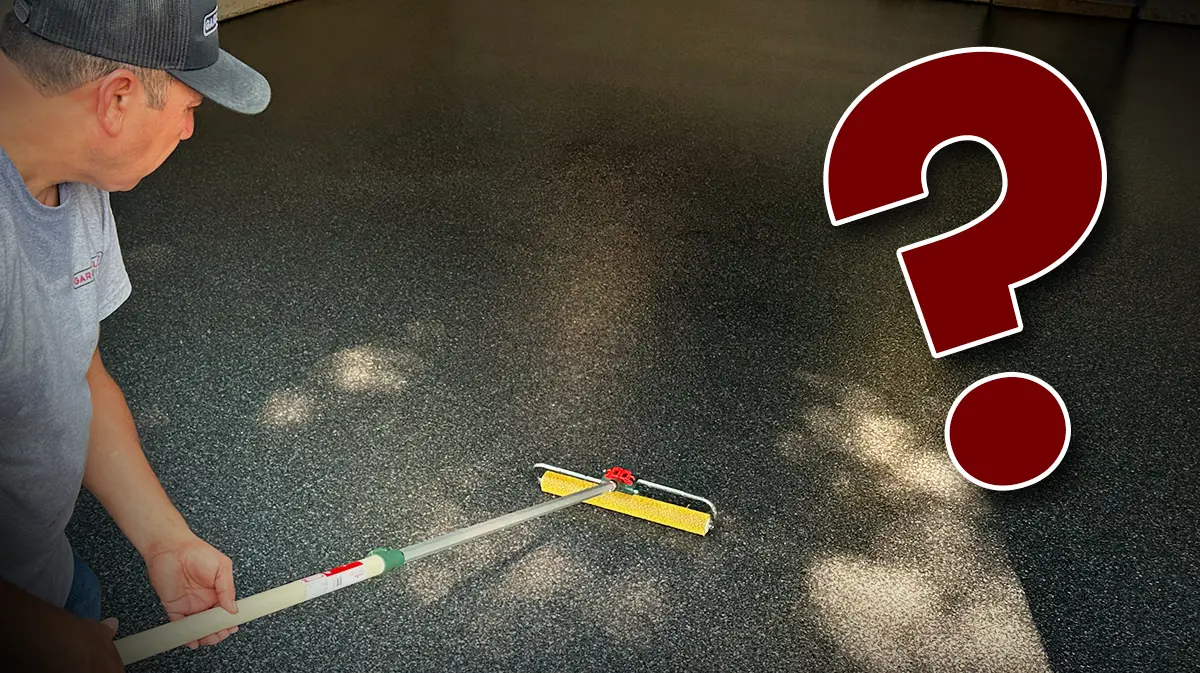

- Thin Layers: Polyurea-polyaspartic coatings are applied in thin layers. These thin coats don’t offer the same protection against moisture and wear that thicker systems do.

- No Moisture Mitigation: The absence of a moisture-mitigating epoxy primer means the coating is more vulnerable to moisture transmission from the concrete. Over time, this can lead to peeling, cracking, or delamination.

- Limited Durability: While polyurea and polyaspartic are excellent top coats, they are lousy primer coats in the presence of concrete moisture. Without proper surface preparation and bonding, the floor will not stand up to heavy use or Ohio’s freezing winters and humid summers.

- Exclusion of Warranties: Many 1-day systems come with warranties that exclude moisture-related damage, leaving you unprotected if issues arise.

2-Day Garage Floor Coating: The Benefits

By contrast, a 2-day system offers a more thorough, long-lasting solution to homeowners. Though it takes an extra day, the results speak for themselves. Here’s why a 2-day epoxy and polyaspartic system is worth the wait:

- Moisture Mitigation: The 2-day system begins with a slower-curing, high-build, 100%-solids moisture-mitigating epoxy primer that bonds to the concrete and prevents moisture from seeping through, protecting the coating from delamination.

- Thicker Coating: With the high-build epoxy and two layers of 100%-solids polyaspartic topcoats, the total thickness of the system reaches over 35 mils, providing a durable, resilient surface.

- Increased Durability: The 100%-solids polyaspartic topcoats are UV-resistant, stain-resistant, and protect against hot-tire transfer. They’re ideal for garages that see a lot of use. (1-day systems use polyaspartic that are significantly less than 100% solids).

- Weather Resistance: In Akron and Cleveland, where weather patterns fluctuate between humid summers and freezing winters, the 2-day system provides better protection against moisture-related damage.

Why the 2-Day System is Perfect for Ohio’s Climate

Ohio’s weather can be tough on garage floors. The freeze-thaw cycles during the winter months can cause moisture to build up in the concrete, leading to cracks and peeling if your coating isn’t properly sealed. In the summer, hot tires can lead to coating failure if the system isn’t designed to handle high temperatures. The 2-day epoxy and polyaspartic system is built to withstand these challenges:

- Freeze-Thaw Protection: The moisture-mitigating epoxy primer ensures that your garage floor can handle Ohio’s cold winters without cracking or peeling.

- Hot Tire Resistance: The dual polyaspartic topcoats protect your floor from hot tire transfer, a common issue during the summer months.

- Long-Term Durability: With the thicker layers and moisture protection, this system is designed to last for years, providing a strong return on your investment.

Call Us for a Free Quote

At GarageFloorCoating.com, we believe in doing the job right. If you want an epoxy floor that will stand the test of time, reach out to us today for a free quote. We’ll walk you through the process and make sure you get the quality floors you deserve.