In the Akron and Cleveland area, with its snowy winters and humid summers, garage floors take a beating. Epoxy flooring offers a strong, durable solution, but there’s more to it than just applying the product. One of the many secrets to a long-lasting, high-quality epoxy floor lies in one critical step: epoxy mixing.

The formula behind epoxy is simple—two parts, a resin (Part A) and an activator (Part B). But don’t let the simplicity fool you. Getting the mix right is crucial to ensure that your floor can withstand everything from icy slush to summer heat waves. Here’s why it matters.

The Importance of a Balanced Mix

The strength of epoxy floor coating comes from how precisely you combine Part A and Part B. Different products require different ratios—1:1, 2:1, 3:2 or 4:1. Sometimes, a solvent must be added to achieve the right consistency. In Northeast Ohio, where temperatures fluctuate and moisture is a constant challenge, precision epoxy mixing ensures your epoxy floor holds up through it all.

Epoxy Mixing: The Top Three Mixing Mistakes

Mistakes in mixing can lead to big problems down the road. Here are three of the most common errors:

- Inaccurate Measuring: Even a slight deviation in the ratio of resin to activator can weaken the final coating. That’s why we rely on tools like an Electronic Coatings Calculator to make sure everything is measured to the exact amount.

- Improper Tools: You need more than a stir stick to get the job done. A high-speed drill with the correct mixing blade ensures the mix is smooth and free of air bubbles, which can compromise the finish.

- Mixing Different Products: Combining parts from different epoxy lines is a rookie mistake. Double-checking labels and staying organized can prevent this.

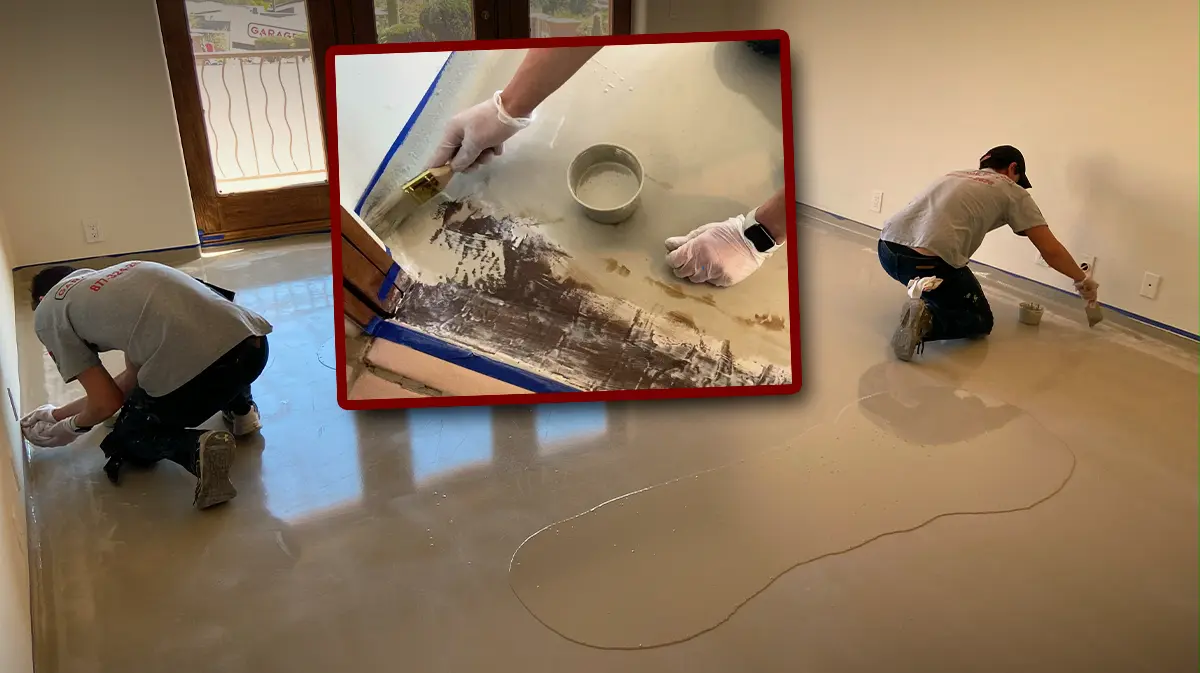

Epoxy Mixing: Our Professional Process

We’ve mastered the art of epoxy mixing. Here’s how we make sure our Akron and Cleveland customers get the best results:

- Mix in the Right Order: We start by thoroughly mixing Part A, especially if it’s pigmented, to make sure the color is even. After that, we slowly add Part B, blending carefully to avoid air bubbles.

- Clean, Controlled Space: We keep the mixing area clean and free from dust, which is especially important in Ohio’s fluctuating climate, where debris can easily find its way into the mix.

- Consistency Is Key: If we’re working with multiple containers of Part A, we pre-mix them together to ensure uniform color and texture across the entire floor.

Why It Pays to Hire Professionals in Northeast Ohio

Ohio’s unpredictable weather—think freezing winters and steamy summers—means that DIY epoxy floor projects often fail. A poorly mixed epoxy can bubble, crack, or peel, leaving a floor that doesn’t last. That’s why trusting professionals is crucial.

We can tailor the epoxy mix to suit Northeast Ohio’s unique climate, ensuring a long-lasting, durable surface. With our expertise, you’ll get a garage floor that looks great and performs beautifully—no matter what the Ohio weather throws its way.